Lighting for industrial facilities

Lighting for industrial facilities

• Lower operating lamps temperature, power supplies and drivers in relation to the equivalent classical LED lamps • The used power supply are more efficient, of lower costs and longer shelf-life • Higher efficiency compared to conventional lamps, and almost all other equivalent LED lamps • Less load on air conditioning • Possibility of redundant power supplies for maximum requirements in terms of the functioning of the light system. • Multiple redundancy and excessive size of the critical elements • Easier servicing – power supply and drivers are available without climbing • Simple, fast and inexpensive installation • The possibility of failure alert • Minimal maintenance (cleaning)

• Purchase of the system directly from the manufacturer, elements customized to specific project • Simple and inexpensive implementation of advanced functions (automatic control, remote monitoring, continuous operation in case of power failure, night light, etc.) • The highest reliability of the system components and the system as a whole • The longest service life (> 100.000h) warranty to 10 years • Lowest total cost of ownership (TCO) per unit of light (lx) • Project funding of up to 3 years • Excellent investment - ROI in most cases 1 - 3 years, net profit remains up to 10 years • With regard to (in Serbia) expected, significant increase in electricity prices in the future, the lowest power consumption is of particular importance. • Low fire risk

• Minimal power consumption • Reduced CO2 emissions, environmental pollution and the greenhouse effect. • Products in accordance with EU RoHS directive • For a long service life, the least waste is generated • THE PRODUCTS are designed for easy recycling

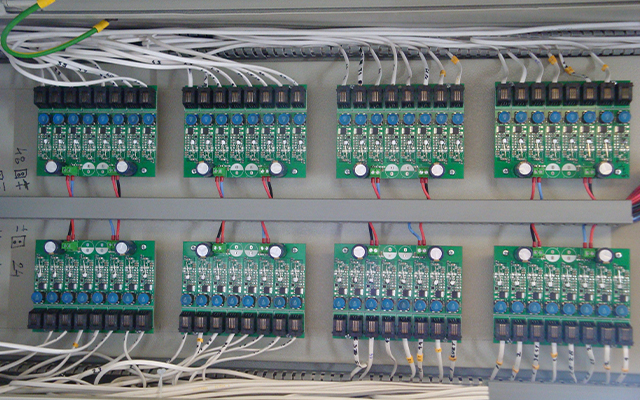

Integra Lighting Systems Lighting Systems consist of the following elements:

• Electrical - cabinet or 19 "rack, with the disassembling and other elements • Power supply, one or more • Optional battery - pack • The central control unit • Drivers • Sensors CENTRAL CONTROL AND POWER

• Switches • Other input devices • Cables • Luminaries • Software • Modem

Quality and efficient lighting as the basis of successful business

New name in the world of lighting

1997 - We have implemented the first systems for lighting control, as a subcontractor of HELVAR company 2000 - Start of production activities 2002 - Design and production of LED tape for light commercials 2004 - We have designed our own production 2007 - Start of machine (automatic) installation 2009 - Start of considerable increase of the capacity of the machine park (equivalent to> 1,000,000 lamps per year) 2010 - Acquisition of materials exclusively through the official distribution channels 2012 - Start of LED lamps production 2013 - Implementation of QMS ISO9001 2014 - Delivery of the first lighting systems with central power supply 2016 - Start of mass production of LED lighting systems with central power supply and management of ISO9001 to Integra Lighting Systems in preparation 2017- Integra Lighting Systems establishment and separation from the parent business

Integra Lighting Systems is the new name in the world of lighting, but it is based on decades of experience in the design and mass production of electronic devices. Defined and controlled processes, carefully selected components and materials of the latest generation and close collaboration with suppliers, are the guarantee of quality and optimized costs. A good team at the firm, as well as a wide range of competent staff guarantee products in the world top

Integra Lighting Systems is the new name in the world of lighting

Step into the future of LED lighting

Low cost with flawless reliability and longest life

Quality and efficient lighting as the basis of successful business

Poor and inefficient light in the business not only means high costs for electricity and therefore proportionally environmental pollution

Our customers are very satisfied with the results achieved at all levels